-

US | en

Electrostatic Cell Sorting

A cell sorter, such as the S3e™ from Bio-Rad, provides the ability to separate cells identified by flow cytometry. Droplet based cell sorters first analyze the particles but also have hardware that can generate droplets and a means of deflecting or directing wanted particles into a collection tube. Droplets can be formed by using high-frequency (cycles/second, Hz) vibration of the nozzle at an optimal amplitude (in volts) over a period of time. This is typically created by a piezoelectric crystal.

Types of Cell Sorters

There are two types of electrostatic sorters, which differ where the particles are interrogated by the laser. Sense-in-air sorters illuminate particles as they exit the nozzle and enter the stream. In cuvette sorters, particles are illuminated in a quartz cuvette before they enter the stream. After the particles are illuminated at what is called the interrogation point, they continue down the stream. Data collected from the particles as they pass through the lasers at the interrogation point is sent to a computer, where the decision is made whether a given particle meets the criteria the user has defined for a desired particle. As the particle continues to travel down the stream, the stream eventually breaks into droplets and the particle of interest is captured in a drop. To prevent the break-off point happening at random distances from the nozzle and to maintain consistent droplet sizes, the nozzle is vibrated at high frequency.

Drop Delay

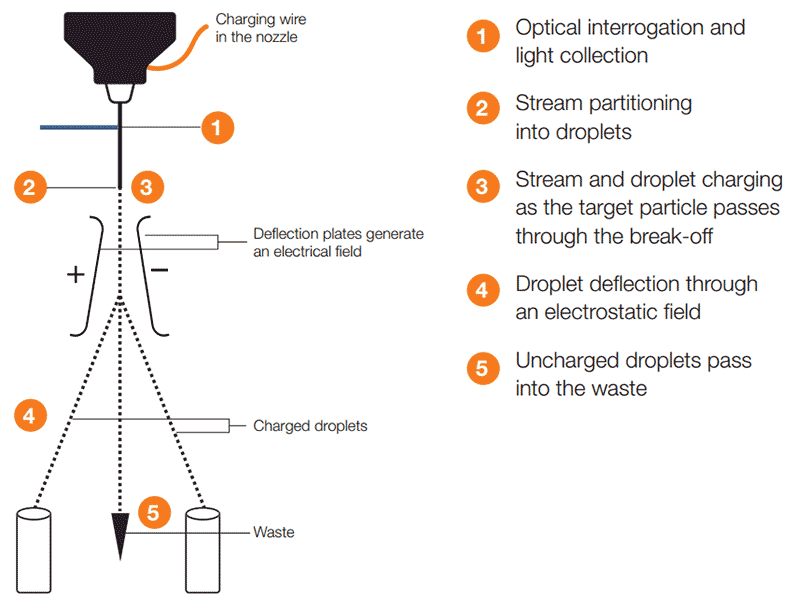

One of the most critical parameters of sorting is to measure the time between the point of interrogation and the exact point where the droplet breaks off. The time and therefore the distance is called the drop delay. When the particle gets to the last connected drop, the entire stream is charged at the nozzle. As the particle of interest-containing drop breaks off, the drop becomes charged. The droplet then passes through an electrical field, and is deflected into a tube or plate. Uncharged particles pass into the waste (Figure 6).

The speed of cell sorting depends on several factors, including particle size and the rate of droplet formation. A typical nozzle is 70-130 μm in diameter and can produce 10,000-90,000 droplets per second. The stability of the break-off dictates the accuracy of the sorting.

Common Usage

Common uses of cell sorting include analysis of identified cell populations and single cells in subsequent downstream applications where DNA, protein or cellular function is investigated. Purifying cells based on markers such as CD34 in hematopoietic stem cells or viability is often used, as is selecting cells, either in populations or single cell cloning, for further culture. Find out more about the first truly walk-away automated cell sorter, the S3e, to see how it could make you cell sorting easier and accessible to both novices and experts.

Fig. 6. Electrostatic flow sorting